QUALITY

alukrom qualıty assurance

Monitored Quality From Raw Material To Installation

Acceptance of Goods-Red Zone

We receive thousands of goods every year. We strictly control any purchase materials at our doorstep prior to the manufacturing process.

Any damaged or out-of-standard materials are rejected at the red zone and returned to trades for replacement.

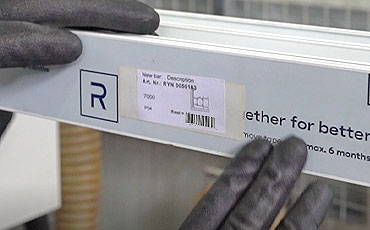

Barcode Monitored Production

We maintain a barcode-monitored production facility where each material is assigned a unique barcode indicating project particulars and aspects of the material, before manufacturing. Personnel processes the barcode at each station to limit possible production defects.

Quality Control

We apply our accredited international quality standards at every production line step until the completion. Then, our Quality Control Manager makes the final check and approves the production before packaging.

Packaging and Delivery

All our aluminium products are protected with removable tapes and are packed with air-bubbled plastic wraps to prevent any damage.

Manufactured products are then delivered to the sites with wooden crates or metal stillages where applicable. We work with FORS-certified logistic companies to transport goods to our sites.

Installation

We have in-house and external installers we work closely with for our local projects. In addition, we work with local installation subcontractors with a proven track record of successful completion through Tier A contractors and developers for our overseas schemes.

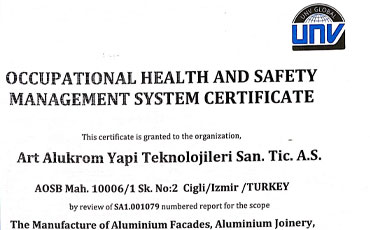

Quality Certificates

Please see our Certificates page to view our up-to-date certificates.

Go to CERTIFICATES page.